The Environmental Impact of Alfalfa Pellet Production: Sustainable Practices and Solutions

The production of alfalfa pellets plays a crucial role in the agricultural and livestock industries…

The production of alfalfa pellets plays a crucial role in the agricultural and livestock industries by providing a reliable, nutrient-rich feed source for animals. However, like any industrial process, pellet production also carries a potential environmental impact, particularly in terms of energy consumption, waste generation, and carbon emissions. As demand for sustainable and eco-friendly practices…

Introduction In recent years, the global shift toward sustainable agriculture has sparked growing interest in organic poultry farming. Consumers are increasingly seeking poultry products free from synthetic additives, antibiotics, and genetically modified ingredients. To meet this demand, poultry producers must optimize every aspect of their operation—starting with feed. At the heart of organic poultry production…

Installation Challenges and Solutions Engineers who are involved in setting up a biomass pellet plant often face a series of challenges that can significantly impact the overall efficiency and productivity of the facility. One common issue is site preparation. Ensuring that the site is adequately prepared involves thorough surveying to detect potential obstructions or land…

Introduction to Fertilizer Granulator Machines Fertilizer granulator machine plays a crucial role in the agricultural and industrial sectors by transforming raw fertilizer materials into granules. These granules are easier to handle, store, and apply, thereby enhancing their usability and effectiveness. Typically, these machines are employed to process a range of materials including urea, ammonium sulfate,…

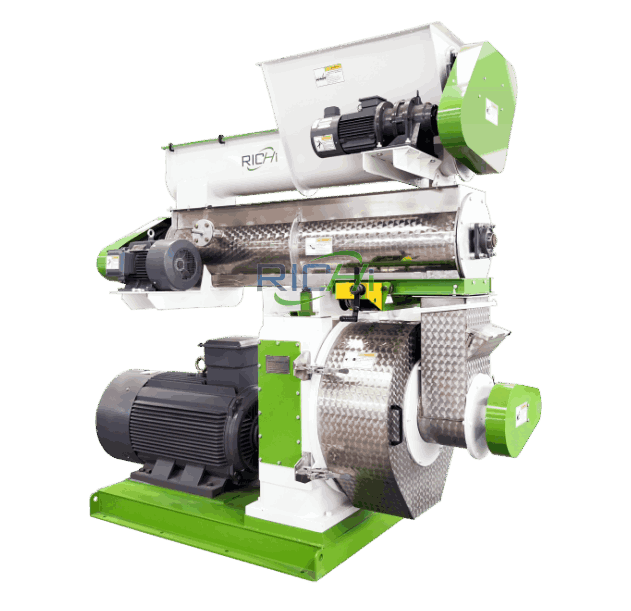

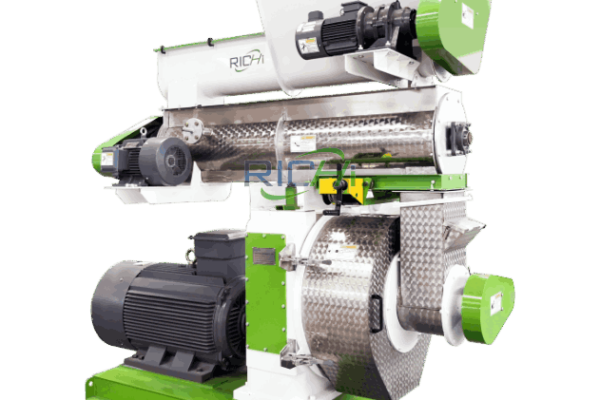

Animal feed pellet machines are essential tools in the agricultural and livestock industries. These machines are engineered to transform raw materials, such as grains and fodder, into compact pellets that are easier for animals to consume and digest. Their primary function is to compress feed materials under high pressure and temperatures, thereby enhancing their nutritional…

The Alfalfa Pellet Production Line is primarily designed for processing alfalfa into compact, manageable pellets. However, many farmers and feed manufacturers wonder if this production line can be adapted to process cattle feed. This article explores the potential for using an Alfalfa Pellet Production Line for cattle feed processing, considering the similarities, differences, and necessary…

Livestock feed pellet machines are versatile tools designed to convert various feed ingredients into compact, digestible pellets. As the need for efficient and nutritious animal feed rises, many farmers and feed manufacturers are considering the production of silage pellets. This article explores whether livestock feed pellet machines can effectively process silage into pellets, the challenges…

Fish feed pellet making machines are crucial for aquaculture operations and feed manufacturing businesses. Their prices can vary widely based on several factors, including size, capacity, features, and the manufacturer. This article delves into the pricing tiers of fish feed pellet making machines, the elements influencing their costs, and essential considerations for prospective buyers. Price…

Shrimp feed pellet machines are essential in the aquaculture industry, especially for shrimp farming. These machines are designed to produce high-quality feed pellets that meet the nutritional requirements of various shrimp species at different growth stages. With the increasing demand for shrimp feed, manufacturers have developed several types of shrimp feed pellet machines to cater…

Establishing a feed mill factory with a capacity of 15 tons per hour (t/h) represents a significant investment in the animal feed production sector. The equipment costs constitute a substantial portion of the overall investment. This article provides an in-depth breakdown of the main equipment costs associated with a 15t/h feed mill factory, reflecting industry…