Animal feed pellet machines are essential tools in the agricultural and livestock industries. These machines are engineered to transform raw materials, such as grains and fodder, into compact pellets that are easier for animals to consume and digest. Their primary function is to compress feed materials under high pressure and temperatures, thereby enhancing their nutritional value and storability. Understanding the working parameters and benefits of these machines is crucial for anyone looking to optimize their animal feed production process.

Key Specifications of Animal Feed Pellet Machines

One of the most critical features of an animal feed pellet machine is its production capacity, which can range from several hundred kilograms to several tons per hour, depending on the model. Small-scale machines typically cater to small farms, while industrial-grade variants are designed for large feed mills.

Dimensions are another vital aspect to consider, especially when space is a constraint. Compact models are available for smaller operations, while larger machines require ample space for installation and operation. Additionally, most models are designed to be user-friendly, featuring automated and semi-automated controls to simplify the pelletizing process.

Price Range and Cost Factors

The cost of animal feed pellet machines fluctuates widely, influenced by factors such as production capacity, material quality, and additional features like automated feeding systems and precision settings. Entry-level models may start at a few thousand dollars, whereas high-end industrial models can exceed tens of thousands of dollars. Prospective buyers should consider long-term benefits and operational efficiency, as investing in a more advanced model can result in better feed quality and lower operational costs over time.

In conclusion, understanding the specifications, functionality, and cost aspects of animal feed pellet machines can significantly impact their effectiveness in feed production. Choosing the right machine tailored to the specific needs of your operation ensures optimal performance and profitability.

Market Analysis and Profit Point Analysis

The market for animal feed pellet machines is experiencing notable growth, driven by the expanding demand for efficient feed production in the poultry, cattle, and aquaculture industries. The increasing need for high-quality feed, combined with the pursuit of cost-effective production methods, underscores the pivotal role of these machines in modern agricultural practices. Recent trends indicate a surge in the adoption of animal feed pellet machines, fueled by their ability to enhance feed quality and production efficiency, which ultimately translates into higher profitability for farmers and feed producers.

In the poultry sector, the demand for animal feed pellet machines is particularly strong, as these machines facilitate the production of uniform, high-nutrient pellets that cater to the dietary needs of various avian species. This not only improves feed utilization rates but also enhances overall flock health, driving up productivity and profitability. Similarly, cattle farmers are increasingly investing in these machines to streamline feed production processes, reducing labor costs and feed wastage while optimizing the growth and health of livestock.

The aquaculture industry also stands to benefit significantly from the use of animal feed pellet machines. With the global demand for seafood on the rise, aquaculture operations are under pressure to produce high-quality, nutritionally balanced feed to sustain healthy fish populations. Animal feed pellet machines offer a solution by enabling the precise formulation and delivery of feed, thus improving feed conversion ratios and economic outputs in aquaculture ventures.

Profitability analyses reveal that the initial investment in animal feed pellet machines can be swiftly offset by the resultant gains in production efficiency and cost savings. Factors such as reduced feed wastage, lower labor costs, and enhanced feed quality contribute to substantial return on investment (ROI). Case studies highlight scenarios where farmers and feed producers have achieved marked improvements in operational efficiency and profit margins by integrating these machines into their production systems.

Overall, the market dynamics for animal feed pellet machines are robust, with significant growth potential across multiple sectors. As producers continue to seek sustainable, efficient methods to meet the escalating demand for high-quality animal feed, the adoption of these machines is poised for further expansion, translating into profitable outcomes for stakeholders in the agriculture and aquaculture industries.

Classifications and Industry Application

Animal feed pellet machines are essential components in modern animal husbandry and aquaculture, significantly contributing to the efficiency and effectiveness of feed production. These machines can be classified based on the type of animals they serve, including poultry (chickens), livestock (cattle), and aquatic species (fish). Each classification addresses distinct requirements and ensures optimal feed formulations for various animal categories.

Chickens

Feeds for chickens require precise blending of nutrients to ensure healthy growth and egg production. The animal feed pellet machines designed for poultry focus on creating uniformly sized pellets that are easy for chickens to consume and digest. The process begins with raw material intake, which includes ingredients such as corn, soybean meal, and vitamins, which are then ground into finer particles. The mixture is conditioned with heat and moisture before being pressed through a die to form pellets. The resulting product is cooled and packed for distribution. These machines are advantageous due to their ability to produce high-quality feed efficiently, which can lead to healthier poultry and higher productivity for poultry farms.

Cattle

Cattle feed pellet machines are engineered to handle fibrous agricultural residues and other bulky raw materials like alfalfa, straw, and grains. The principle is similar to that of poultry feed machines but adapted to accommodate rougher and larger feed components. These machines grind the materials, often incorporating molasses for added energy, followed by conditioning and pelleting. The ability to transform coarse materials into digestible pellets aids in better feed efficiency and weight gain in cattle, making them indispensable for dairy and beef production industries.

Fish

For fish, the feed pellet machines must produce water-stable pellets that do not disintegrate quickly. Aquatic feed formulations often include fish meal, soybean meal, and other ingredients rich in protein and fats. The process involves fine grinding, extrusion, and pelleting with specialized equipment designed to enhance water stability and floatability for specific species. The precise configuration of these machines supports the nutritional adequacy of the feed, aiding in the healthy growth and survival rates of farmed fish, which is crucial for aquaculture ventures.

Across these various classifications, animal feed pellet machines exhibit versatile applications in agriculture and livestock domains. Their ability to produce tailored feed formulations ensures that animals receive the optimal balance of nutrients, thereby addressing specific industry needs. This targeted approach not only supports animal health but also enhances the economic viability of farming operations by improving feed efficiency and reducing waste.

When it comes to selecting the most suitable animal feed pellet machine and supplier, several critical factors should be considered to ensure high efficiency and quality in your production line. Firstly, evaluate the experience and expertise of the supplier. A well-established supplier with a history of successful projects is often a reliable choice. Another necessity is the customization options available; a supplier capable of tailoring machines to your specific needs can significantly enhance your operational efficiency.

Choosing a supplier that offers turnkey solutions can simplify your project management. Turnkey solutions ensure that your entire production process, from initial design to final implementation, is handled by one expert team, offering a seamless experience. This reduces the risk of miscommunication and potential delays that may arise when dealing with multiple vendors.

Introducing Richi Machinery

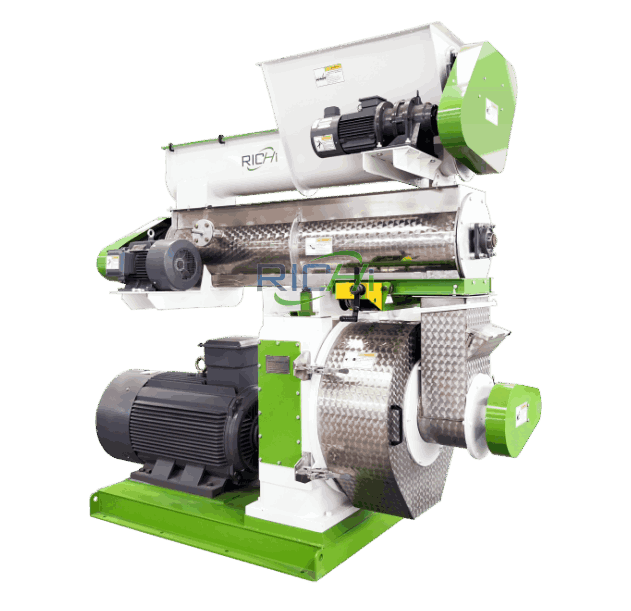

Richi Machinery stands out in the industry as a leading manufacturer of animal feed pellet machines, recognized for its extensive expertise and innovative solutions. As one of the most professional pellet mill manufacturers in China, Richi Machinery has a large manufacturing capacity and a proven track record of delivering high-quality turnkey projects globally. The advanced technology utilized in Richi Machinery’s designs ensures superior performance and longevity of their products.

There are numerous benefits to choosing Richi Machinery as your supplier. The company emphasizes cutting-edge technology, which translates to higher efficiency and reliability in production. Customers also benefit from the high-quality materials used in the construction of Richi’s pellet machines, ensuring durability and robust performance under intensive use. Additionally, Richi Machinery provides comprehensive customer support, assisting clients from the initial consultation throughout the lifespan of the machine, ensuring optimal operation and minimal downtime.

Richi Machinery’s commitment to innovation and customer satisfaction positions it as a leader in the field. By integrating advanced technology and offering unparalleled customer service, they deliver exceptional value, making them the ideal choice for animal feed pellet machine needs.

Frequently Asked Questions

Investing in an animal feed pellet machine requires thorough understanding of its functionality, maintenance, and usability. Below, we address some of the most common questions to aid prospective buyers in making informed decisions.

What are the maintenance requirements for an animal feed pellet machine?

Regular maintenance is crucial for ensuring the longevity and optimal performance of an animal feed pellet machine. Routine tasks include cleaning the machine after every use, lubricating moving parts, and periodically checking for wear and tear. It is also advisable to follow the manufacturer’s maintenance schedule, which typically includes more detailed inspections and part replacements. Neglecting these activities may lead to machine failures and reduced productivity.

How long does it take to install a pellet production line?

The installation time for a pellet production line can vary based on the complexity and scale of the setup. Typically, it takes between a few days to a couple of weeks. Factors influencing this duration include the availability of required materials, the readiness of the installation site, and the experience of the installation team. Coordination and pre-planning can significantly reduce installation time, enabling quicker operational readiness.

What are the best practices for optimizing pellet quality?

Optimizing pellet quality involves several key practices. First, ensure that the raw materials are of high quality and adequately prepared for pelletizing. Second, maintain consistent moisture levels, as fluctuations can affect pellet durability and nutritional value. Third, ensure that the die and roller settings are appropriately adjusted according to the material being processed. Proper cooling and storage of the finished pellets are also vital to prevent degradation and maintain feed quality over time.

Considering the complexities and requirements of operating an animal feed pellet machine, it’s essential to stay well-informed and adopt best practices. This approach will not only improve efficiency but also enhance the return on investment.