The energy efficiency of a Ring Die Alfalfa Pellet Making Machine plays a crucial role in determining the overall operational costs of alfalfa pellet production. As energy consumption represents a significant portion of the production expenses, understanding and optimizing the machine’s energy efficiency can lead to substantial cost savings and improved profitability.

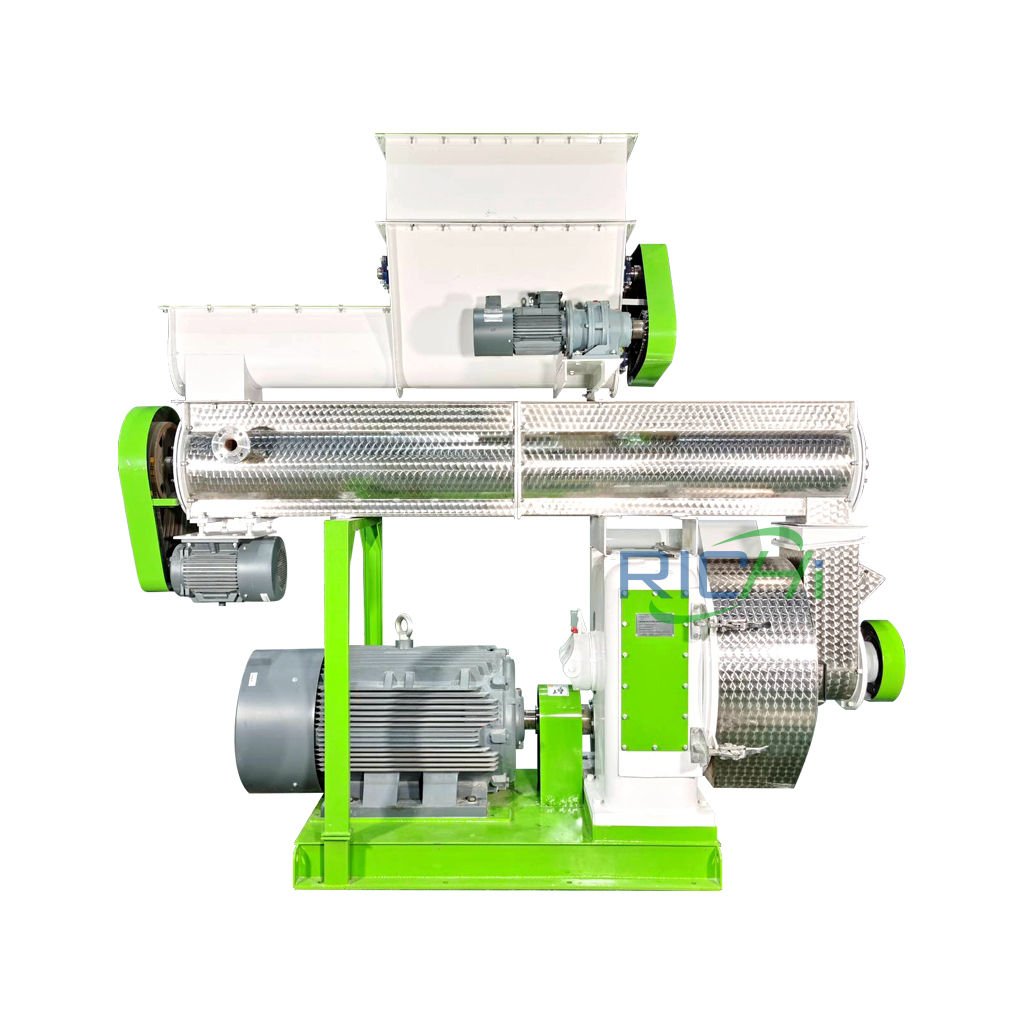

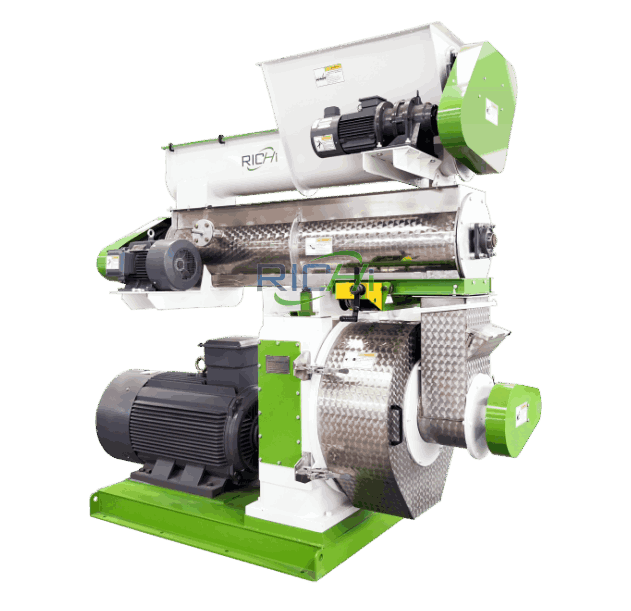

This article explores how the energy efficiency of Ring Die Alfalfa Pellet Making Machines impacts costs and discusses strategies for maximizing efficiency.Understanding Energy Consumption in Alfalfa Pellet ProductionAlfalfa pellet production is an energy-intensive process, with the pellet making machine being the primary consumer of energy. The main energy-consuming components of a Ring Die Alfalfa Pellet Making Machine include:

- The main motor driving the ring die and rollers

- The conditioning system (steam or water addition)

- The feeding system

- Auxiliary equipment such as conveyors and cooling systems

The energy efficiency of these components directly affects the overall energy consumption and, consequently, the production costs.

Impact of Energy Efficiency on Production Costs

- Direct Energy Costs

The most obvious impact of energy efficiency is on direct energy costs. A more efficient machine consumes less electricity per ton of alfalfa pellets produced, leading to lower energy bills. For example, an improvement in energy efficiency from 70% to 80% could result in a 12.5% reduction in energy costs, which can be significant for large-scale operations. - Production Capacity and Throughput

Energy-efficient machines often have optimized designs that allow for higher production capacities and improved throughput. This means more pellets can be produced in the same amount of time, spreading fixed costs over a larger production volume and reducing the per-unit cost of pellets. - Maintenance and Longevity

Efficient machines typically experience less wear and tear due to optimized operations. This can lead to reduced maintenance costs and extended equipment lifespan, further contributing to cost savings over time. - Quality of Pellets

Energy-efficient machines often produce higher quality pellets with better durability and consistency. This can lead to premium pricing for the end product, offsetting production costs and improving overall profitability.

Factors Affecting Energy Efficiency

Several factors influence the energy efficiency of Ring Die Alfalfa Pellet Making Machines:

- Machine Design: The design of the ring die, rollers, and other components significantly impacts energy efficiency. Modern, optimized designs can greatly improve efficiency.

- Raw Material Preparation: Proper grinding and moisture content of alfalfa can reduce the energy required for pelletization.

- Die and Roller Configuration: Optimal die hole size, length-to-diameter ratio, and roller gap settings can minimize energy consumption while maintaining pellet quality.

- Conditioning Process: Efficient steam or water addition during conditioning can reduce the energy required for pelletization.

- Operating Parameters: Maintaining optimal speed, temperature, and pressure settings can significantly impact energy efficiency.

Strategies for Improving Energy Efficiency

- Invest in Modern Equipment: Newer Ring Die Alfalfa Pellet Making Machines often incorporate energy-efficient designs and technologies.

- Optimize Raw Material Preparation: Ensure proper grinding and moisture content of alfalfa before pelletization.

- Regular Maintenance: Keep the machine in top condition through regular maintenance to prevent energy losses due to wear and tear.

- Monitor and Adjust Operating Parameters: Continuously monitor and adjust speed, temperature, and pressure settings for optimal efficiency.

- Implement Energy Recovery Systems: Utilize heat recovery systems to capture and reuse waste heat from the pelletization process.

- Use Variable Frequency Drives (VFDs): Implement VFDs on motors to optimize energy consumption based on load requirements.

- Train Operators: Properly trained operators can run the machine more efficiently, reducing energy waste.

Cost-Benefit Analysis of Energy Efficiency Improvements

When considering investments in energy efficiency improvements for Ring Die Alfalfa Pellet Making Machines, it’s essential to conduct a thorough cost-benefit analysis. This should include:

- Initial investment costs for new equipment or upgrades

- Projected energy savings over time

- Potential increases in production capacity and throughput

- Reduced maintenance costs and extended equipment lifespan

- Improved product quality and potential for premium pricing

In many cases, the long-term benefits of improved energy efficiency can far outweigh the initial investment costs, leading to significant savings and improved profitability over time.ConclusionThe energy efficiency of Ring Die Alfalfa Pellet Making Machines has a profound impact on production costs and overall profitability in alfalfa pellet production.

By understanding the factors that influence energy efficiency and implementing strategies to optimize machine performance, producers can significantly reduce energy consumption, lower production costs, and improve their competitive edge in the market.

As energy prices continue to fluctuate and environmental concerns grow, investing in energy-efficient pellet making machines and optimizing their operation becomes increasingly important. Producers who prioritize energy efficiency in their operations will be better positioned to manage costs, improve product quality, and maintain profitability in the long term.

Related post: alfalfa pellet production line