In the world of organic fertilizer production, the ease of maintenance for pellet machines is a crucial factor that can significantly impact operational efficiency and long-term costs. While many brands offer quality machines, some stand out for their user-friendly designs and simplified maintenance procedures. This article explores the organic fertilizer pellet machine brands known for their straightforward maintenance requirements.

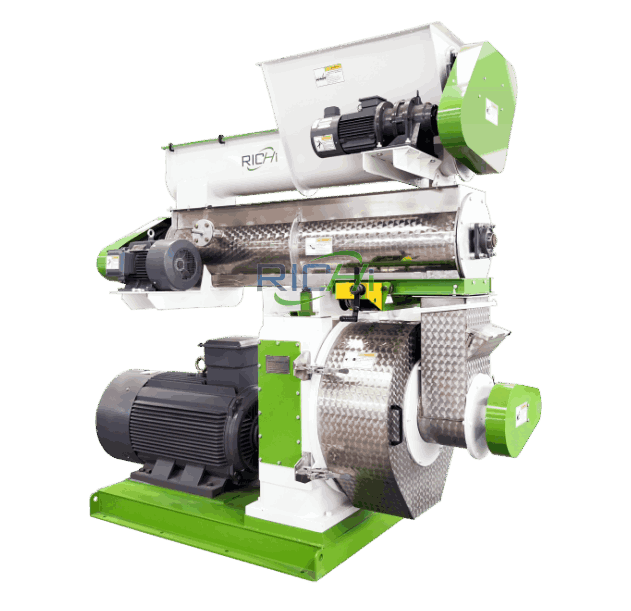

- RICHI Machinery

RICHI Machinery has established itself as a leader in providing organic fertilizer pellet machines with simple maintenance procedures:

- Modular Design: RICHI’s machines feature a modular design, allowing easy access to different components for cleaning and maintenance.

- Self-Lubricating Systems: Many of their models incorporate self-lubricating systems, reducing the frequency of manual lubrication.

- Easy-to-Replace Parts: RICHI designs their machines with easily replaceable wear parts, minimizing downtime during maintenance.

- Clear Maintenance Guidelines: Each machine comes with detailed, easy-to-follow maintenance manuals and schedules.

The company’s focus on user-friendly designs has made their machines popular among both small-scale farmers and large industrial operations.

- GEMCO Energy

GEMCO Energy is another brand known for its low-maintenance organic fertilizer pellet machines:

- Simplified Control Systems: Their machines often feature intuitive control panels, making it easier for operators to monitor and maintain the equipment.

- Durable Components: GEMCO uses high-quality, wear-resistant materials in critical components, reducing the frequency of replacements.

- Accessible Design: The layout of GEMCO machines allows for easy access to key components, simplifying routine maintenance tasks.

- Automated Cleaning Features: Some models include automated cleaning cycles, reducing the need for manual cleaning.

GEMCO’s approach to maintenance simplicity has made their machines particularly popular in regions where technical expertise may be limited.

- Zhengzhou Fusmar Machinery

Fusmar Machinery has gained recognition for its user-friendly organic fertilizer pellet machines:

- Tool-Free Maintenance: Many of Fusmar’s models feature tool-free access panels, allowing quick inspections and minor maintenance without specialized tools.

- Clear Indicators: Their machines often include clear visual indicators for maintenance needs, such as lubrication points and wear indicators.

- Standardized Parts: Fusmar uses standardized parts across their range, making it easier to stock and replace components.

- Remote Diagnostics: Some advanced models offer remote diagnostic capabilities, allowing for quick troubleshooting and maintenance guidance.

Fusmar’s focus on simplifying maintenance has made their machines a favorite among smaller operations and those new to organic fertilizer production.

- Amisy Machinery

Amisy Machinery offers organic fertilizer pellet machines known for their straightforward maintenance requirements:

- Simplified Cleaning Processes: Amisy’s machines often feature smooth surfaces and removable panels for easy cleaning.

- Extended Service Intervals: Through the use of high-quality materials and efficient designs, Amisy has managed to extend the service intervals for many components.

- User-Friendly Manuals: Amisy provides comprehensive yet easy-to-understand maintenance manuals with each machine.

- Training Programs: The company offers extensive training programs for operators, focusing on efficient maintenance practices.

Amisy’s commitment to simplifying maintenance has made their machines popular in educational institutions and research facilities.

- FTM Machinery

FTM Machinery has built a reputation for producing organic fertilizer pellet mills with minimal maintenance needs:

- Robust Construction: FTM’s machines are built with durability in mind, reducing the overall maintenance requirements.

- Simplified Lubrication Systems: Many models feature centralized lubrication systems, making it easier to maintain proper lubrication.

- Quick-Change Components: FTM designs their machines with quick-change components for parts that require regular replacement.

- Automated Monitoring: Advanced models include automated monitoring systems that alert operators to maintenance needs.

FTM’s focus on reducing maintenance complexity has made their machines attractive to large-scale operations looking to minimize downtime.Key Factors Contributing to Easy MaintenanceAcross these brands, several common factors contribute to simplified maintenance:

- Accessibility: Machines designed with easy access to key components simplify inspection and maintenance tasks.

- Durability: The use of high-quality, wear-resistant materials reduces the frequency of part replacements.

- Automation: Automated cleaning and lubrication systems minimize the need for manual intervention.

- Clear Instructions: Comprehensive yet easy-to-understand maintenance manuals and training programs are crucial.

- Standardization: The use of standardized parts across machine ranges simplifies inventory management and replacements.

- Modular Design: Modular construction allows for easier replacement of individual components without affecting the entire machine.

- Diagnostic Tools: Built-in diagnostic systems help quickly identify and address maintenance needs.

Conclusion

While all organic fertilizer pellet machines require some level of maintenance, brands like RICHI Machinery, GEMCO Energy, Zhengzhou Fusmar Machinery, Amisy Machinery, and FTM Machinery stand out for their efforts in simplifying these processes. These companies have recognized that ease of maintenance is a crucial factor for many operators, particularly those in smaller operations or regions with limited technical expertise.When choosing an organic fertilizer pellet machine, considering the ease of maintenance can significantly impact long-term operational costs and efficiency.

The brands discussed in this article have demonstrated a commitment to user-friendly designs and simplified maintenance procedures, making them excellent choices for those prioritizing easy upkeep.However, it’s important to note that the simplicity of maintenance should be balanced with the machine’s performance, durability, and suitability for specific production needs. Potential buyers should carefully consider their unique requirements, production scale, and available resources when selecting a machine.

As the organic fertilizer industry continues to grow, we can expect further innovations in machine design aimed at simplifying maintenance and improving overall user experience. This trend will likely lead to even more efficient and user-friendly organic fertilizer pellet machines in the future, benefiting operators across the spectrum of production scales.