As the world faces the dual challenges of climate change and the need to feed a growing population, sustainable agricultural practices have become more critical than ever. Organic fertilizers, derived from natural sources such as animal manures, plant residues, and composted materials, offer a viable solution to enhance soil health and boost crop yields while minimizing environmental impact. Establishing an organic fertilizer production project is a significant step towards promoting sustainable agriculture. This article explores the key aspects of such projects, including their benefits, production processes, cost considerations, and future outlook.

The Importance of Organic Fertilizers

Organic fertilizers play a crucial role in sustainable agriculture by providing essential nutrients to plants, improving soil structure, and enhancing microbial activity. Unlike chemical fertilizers, organic fertilizers are environmentally friendly and contribute to the long-term health of the soil. The benefits of organic fertilizers include:

- Improved Soil Health: Organic fertilizers enhance soil structure, water-holding capacity, and microbial activity, promoting long-term soil fertility and reducing the risk of erosion.

- Reduced Environmental Impact: Organic fertilizers do not contribute to water pollution, soil acidification, or greenhouse gas emissions, making them a more environmentally friendly choice.

- Increased Crop Resilience: Plants grown with organic fertilizers often exhibit increased resistance to pests, diseases, and environmental stresses, leading to improved crop yields and quality.

- Nutrient Cycling: Organic fertilizers contribute to the natural cycling of nutrients within the ecosystem, reducing the need for external inputs and promoting a more sustainable agricultural model.

Key Components of an Organic Fertilizer Production Project

Establishing an organic fertilizer production project involves several key components, each playing a vital role in ensuring the project’s success. These components include:

- Raw Material Sourcing and Handling: The first step in organic fertilizer production is sourcing and handling raw materials. Common raw materials include animal manures, crop residues, food waste, and municipal green waste. These materials must be collected, sorted, and preprocessed to ensure they are suitable for composting or fermentation.

- Composting and Fermentation: The preprocessed organic materials undergo a controlled composting or fermentation process, facilitated by specialized equipment and carefully monitored environmental conditions. During this stage, beneficial microorganisms break down the organic matter, releasing nutrients and stabilizing the material.

- Screening and Separation: After composting or fermentation, the material is screened and separated to remove any unwanted contaminants, such as plastics or metals. This step ensures the final product meets quality standards and is free from potential hazards.

- Granulation and Drying: Depending on the desired product form, the organic fertilizer may undergo granulation or pelletization to create uniform, easy-to-handle particles. This process often involves the addition of binding agents and drying to achieve the desired moisture content and physical characteristics.

- Packaging and Storage: The final organic fertilizer product is packaged in various formats, such as bags or bulk containers, and stored in a controlled environment to maintain its quality and prevent degradation until distribution.

- Quality Control and Testing: Ensuring the quality and efficacy of the organic fertilizer products requires investment in quality control and testing facilities. This includes laboratory equipment, testing kits, and personnel for conducting regular quality assessments.

Related post: https://www.richipelletmachine.com/organic-fertilizer-production-plant-cost/

Cost Considerations for Organic Fertilizer Production Projects

The cost of establishing an organic fertilizer production project can vary significantly depending on several factors, including the scale of the project, location, and technology used. Key cost considerations include:

- Land and Site Development: The cost of acquiring land and preparing the site for construction is a significant component of the overall project cost. This includes expenses related to land acquisition, site clearing, grading, and infrastructure development such as access roads, utilities, and drainage systems.

- Plant Design and Engineering: The design and engineering phase involves creating detailed plans and specifications for the organic fertilizer plant. This includes architectural and engineering services, feasibility studies, environmental impact assessments, and obtaining necessary permits and approvals.

- Construction and Civil Works: The construction phase encompasses the building of the plant’s physical infrastructure, including production facilities, storage areas, administrative offices, and utility installations. This component also covers the cost of materials, labor, and construction equipment.

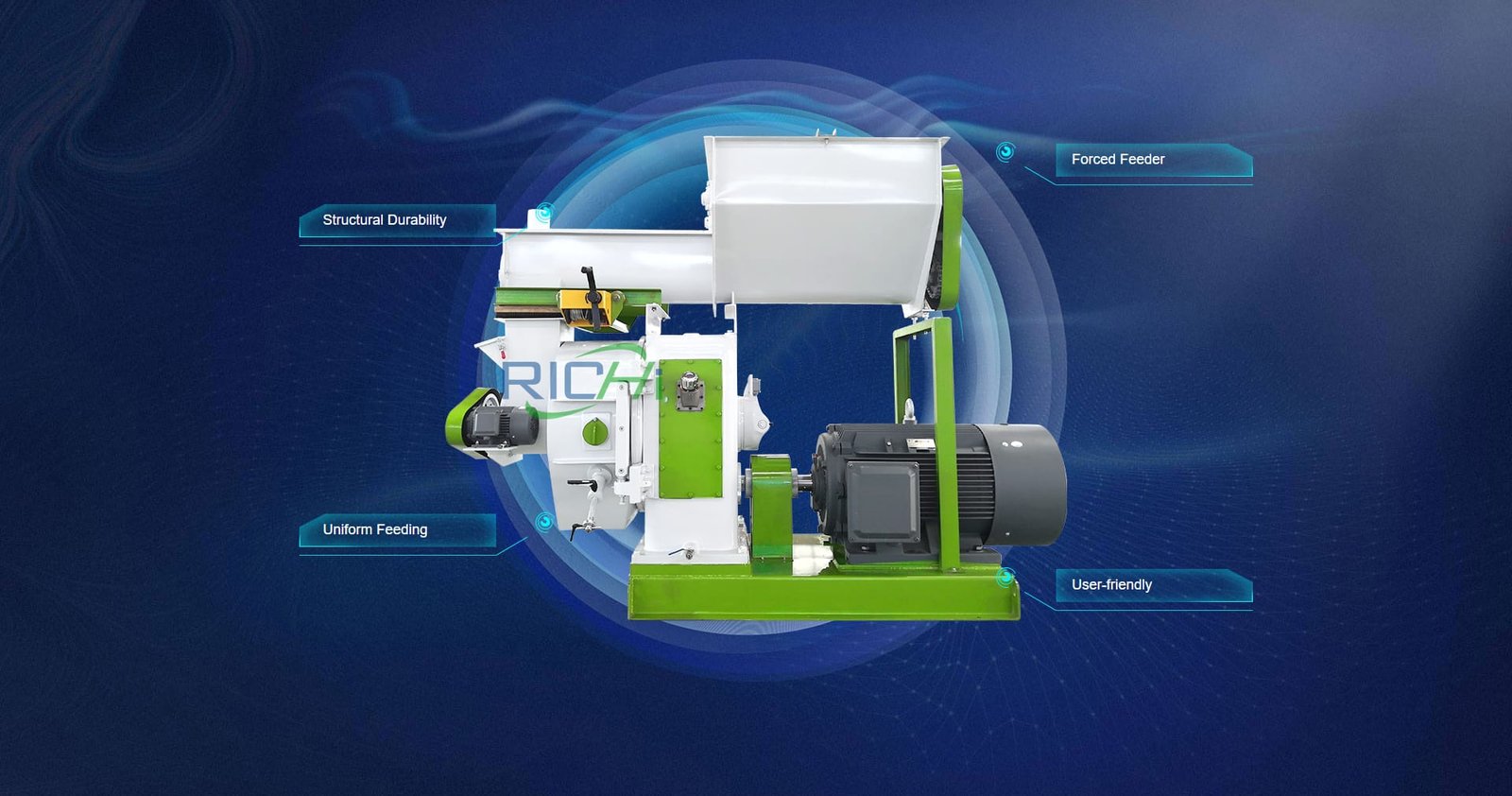

- Machinery and Equipment: The cost of purchasing and installing machinery and equipment is a major component of the project cost. This includes equipment for raw material handling, composting, fermentation, granulation, drying, cooling, and packaging. The choice of technology and equipment can significantly impact the overall cost and efficiency of the plant.

- Raw Materials and Inputs: The cost of raw materials and inputs required for organic fertilizer production, such as organic matter, microorganisms, and additives, must be factored into the project cost. Ensuring a consistent and reliable supply of high-quality raw materials is crucial for the plant’s operation.

- Labor and Staffing: The cost of hiring and training personnel to operate and manage the organic fertilizer plant is an important consideration. This includes salaries, benefits, and training programs for skilled and unskilled workers, as well as administrative and management staff.

- Utilities and Energy: The cost of utilities and energy required to operate the plant, including electricity, water, and gas, must be accounted for. Implementing energy-efficient technologies and practices can help reduce operational costs.

- Marketing and Distribution: The cost of marketing and distributing the organic fertilizer products to end-users is an essential component of the project cost. This includes expenses related to branding, packaging, transportation, and establishing distribution networks.

- Contingency and Miscellaneous Costs: It is prudent to allocate a contingency budget to cover unforeseen expenses and cost overruns. Miscellaneous costs may include legal fees, insurance, and other administrative expenses.

Factors Influencing Project Success

Several factors can influence the success of an organic fertilizer production project, including:

- Feedstock Availability and Quality: The availability and quality of raw materials are critical to the success of the project. Consistent and reliable feedstock supply ensures uninterrupted production and high-quality fertilizer products.

- Technology and Equipment: The choice of technology and equipment used in the production process can influence the cost and efficiency of the plant. Advanced and automated systems may have higher upfront costs but offer long-term benefits in terms of productivity and operational efficiency.

- Location: The location of the plant affects land acquisition costs, availability of raw materials, labor costs, and access to markets. Proximity to raw material sources and target markets can reduce transportation costs and improve operational efficiency.

- Regulatory Compliance: Compliance with local and national regulations, including environmental, health, and safety standards, can impact the project cost. Obtaining necessary permits and adhering to regulatory requirements may involve additional expenses.

- Market Demand: Understanding market demand and consumer preferences is crucial for the success of the project. Conducting market research and developing effective marketing strategies can help ensure a steady demand for the organic fertilizer products.

Future Outlook

The future outlook for organic fertilizer production projects is promising, driven by the growing demand for sustainable agricultural practices and environmentally friendly products. As the global population continues to grow and the impacts of climate change become more pronounced, the need for sustainable solutions in agriculture will only intensify.

Ongoing research and innovation in areas such as nutrient recovery, microbial inoculants, and precision agriculture will further enhance the efficiency and effectiveness of organic fertilizer production and application. Collaborations between industry, academia, and policymakers will be crucial in driving these advancements and fostering a more sustainable and regenerative approach to agriculture.

In conclusion, organic fertilizer production projects represent a vital component of the sustainable agriculture movement, offering a pathway towards a more environmentally conscious and resilient food system. By harnessing the power of organic waste materials and leveraging technological advancements, these projects are poised to play a pivotal role in nourishing the earth, supporting food security, and promoting a healthier planet for generations to come.

For details please contact: Richi Pellet Machine

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com