Shrimp feed pellet machines are essential in the aquaculture industry, especially for shrimp farming. These machines are designed to produce high-quality feed pellets that meet the nutritional requirements of various shrimp species at different growth stages. With the increasing demand for shrimp feed, manufacturers have developed several types of shrimp feed pellet machines to cater to different production needs and scales. This article explores the main types of shrimp feed pellet machines available in the market.

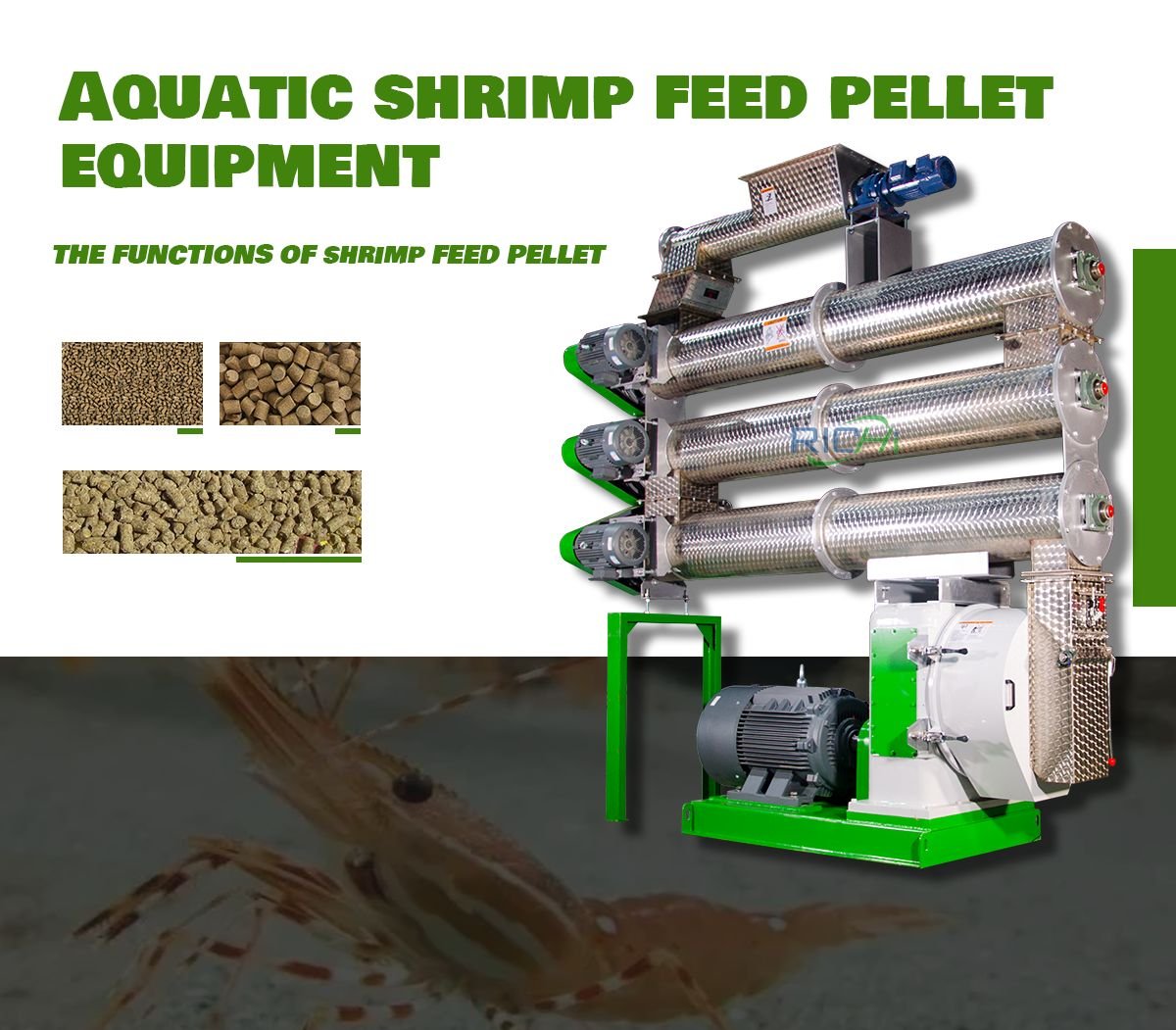

1. Ring Die Pellet Mill

The ring die pellet mill is one of the most commonly used shrimp feed pellet machines. It features a rotating ring die and stationary rollers. The feed mixture is pressed through the holes in the ring die by the rollers, resulting in cylindrical pellets.

Key Features:

- High production capacity

- Suitable for large-scale production

- Capable of handling a wide range of ingredients

- Produces dense, sinking pellets ideal for shrimp

Advantages:

- Cost-effective for high-volume production

- Consistent pellet quality

- Durable and long-lasting

Disadvantages:

- Requires more power compared to other types

- Limited flexibility in adjusting pellet size

2. Flat Die Pellet Mill

The flat die pellet mill uses a stationary flat die and rotating rollers to compress the feed mixture through the die holes. This type of machine is often utilized for smaller-scale production or specialized feed formulations.

Key Features:

- Compact design

- Suitable for small to medium-scale production

- Easy to maintain and clean

Advantages:

- Lower initial investment cost

- Easy die replacement

- Good for producing smaller batches of specialized feed

Disadvantages:

- Lower production capacity compared to ring die mills

- May produce less dense pellets

3. Extruder Pellet Machine

Extruder pellet machines utilize a screw mechanism to force the feed mixture through a die under high pressure and temperature. This process improves starch gelatinization and protein denaturation, resulting in highly digestible pellets.

Key Features:

- Capable of producing floating, slow-sinking, or sinking pellets

- Excellent control over pellet density and expansion

- Suitable for high-fat formulations

Advantages:

- Produces highly water-stable pellets

- Can incorporate higher levels of fat in the feed

- Enhances digestibility of feed ingredients

Disadvantages:

- Higher initial investment cost

- Requires more energy to operate

- More complex operation and maintenance

4. Wet Type Pellet Machine

Wet type pellet machines are designed for feed mixtures with higher moisture content, making them particularly effective for producing shrimp feed pellets that require excellent water stability.

Key Features:

- Processes feed mixtures with up to 65% moisture content

- Produces dense, water-stable pellets

- Often used in conjunction with a dryer

Advantages:

- Excellent for producing high-quality, water-stable shrimp feed

- Can effectively incorporate liquid ingredients

- Reduces dust during production

Disadvantages:

- Requires a drying step after pelleting

- Higher energy consumption due to the drying process

- More complex production line setup

5. Dry Type Pellet Machine

Dry type pellet machines process feed mixtures with lower moisture content. They are simpler in design and operation compared to wet type machines.

Key Features:

- Processes feed mixtures with 10-13% moisture content

- Simpler design and operation

- Often used for smaller-scale production

Advantages:

- Lower initial investment cost

- Simplified production process

- Lower energy consumption

Disadvantages:

- Limited ability to produce highly water-stable pellets

- May not suit all shrimp feed formulations

6. Vertical Pellet Mill

Vertical pellet mills have a unique design where the die and rollers are arranged vertically, providing advantages in terms of space efficiency and gravity-assisted material flow.

Key Features:

- Compact, vertical design

- Gravity-assisted material flow

- Suitable for medium-scale production

Advantages:

- Space-efficient design

- Effective for producing medium-hard pellets

- Easy maintenance due to vertical configuration

Disadvantages:

- May have limitations in processing certain ingredients

- Not as common as horizontal configurations

7. Organic Fertilizer Pellet Machine (Adapted for Shrimp Feed)

Some manufacturers have adapted organic fertilizer pellet machines for shrimp feed production. These machines are capable of handling a wide range of organic materials and can produce shrimp feed pellets with high organic content.

Key Features:

- Can handle various organic materials

- Robust design for processing fibrous ingredients

- Often includes a pre-conditioning step

Advantages:

- Versatile in handling different ingredient types

- Suitable for producing organic or specialty shrimp feeds

- Can process ingredients with varying moisture contents

Disadvantages:

- May require additional modifications for optimal shrimp feed production

- Not specifically designed for aquafeed, which could affect pellet quality

Choosing the Right Shrimp Feed Pellet Machine

When selecting a shrimp feed pellet machine, consider the following factors:

- Production capacity requirements

- Types of shrimp feed formulations to be produced

- Desired pellet characteristics (size, density, water stability)

- Available space and infrastructure

- Budget constraints

- Energy efficiency and operational costs

- Ease of maintenance and availability of spare parts

- Flexibility to produce different types of aquatic feeds

Conclusion

Choosing the appropriate shrimp feed pellet machine depends on various factors, including production scale, feed formulation, desired pellet characteristics, and budget. Ring die and flat die pellet mills are popular choices for their reliability and cost-effectiveness. Extruder pellet machines offer superior control over pellet characteristics and produce highly water-stable pellets. Wet type pellet machines excel in producing high-quality shrimp feed but require a more complex setup. (Related post:fishing pellet making machine)

As the aquaculture industry evolves, manufacturers are continuously innovating to enhance shrimp feed pellet machines. Future developments may include more energy-efficient designs, improved control systems for precise pellet formation, and machines capable of processing a broader range of sustainable ingredients.

Ultimately, the best type of shrimp feed pellet machine for a specific operation will depend on its unique requirements and constraints. By carefully evaluating the options and considering long-term operational needs, shrimp feed producers can select the most suitable machine to ensure the production of high-quality feed pellets that support optimal shrimp growth and farm profitability.